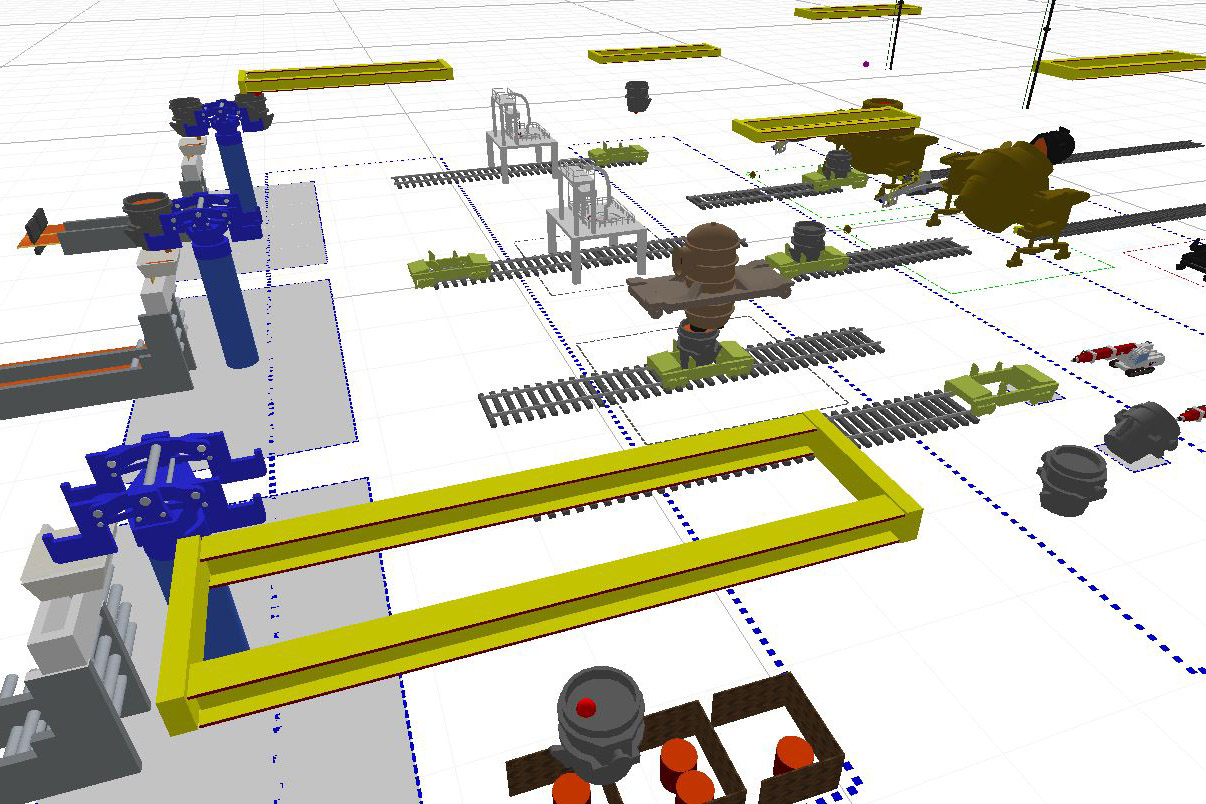

Danieli Corus has developed the Steel Plant Model, a simulation tool that helps optimize logistics in both existing and new BOF steel plants. The model simulates any operational scenario in any BOF steel plant realistically and accurately in 3D and real time. All objects, including equipment, cranes and ladles, communicate. The simulation includes process time deviations, maintenance and breakdowns. Thanks to Smart Cranes interaction, transportation movements are simulated very realistically as well.

With the model, a wide variety of scenarios is analysed in order to

- Identify and eliminate bottlenecks

- Determine the results of modifications in the process (such as adding or improving equipment, different routing or priorities)

- Improve production

- Reduce CAPEX and OPEX

- Optimize a greenfield design

The Steel Plant Model was developed in such a way that when basic information (plant layout and completed questionnaire) is supplied by the client, the first preliminary simulation can be run within a short time. Depending on the client’s request this simulation will be followed by, for example, a more detailed study and report or a web–based HMI that enables client’s engineers to run their own scenarios.